Equipment based on evaporative cooling.

CONTENTS

-

type of towers

-

sizing

-

Facility

1 - TECHNICAL SHEET

2 - OPERATING PRINCIPLE

A cooling tower cools water for acombination of heat and mass transfer. The water to be cooled is distributed in the tower by spray nozzles, splash bars, or film-type fill, which exposes a large amount of water surface area to atmospheric air. Outdoor air is circulated by (1) fans, (2) convective drafts, (3) natural wind currents, or (4) induction effect sprinklers.

A part of the water absorbs heat for the phase change from liquid to vapor at constant pressure. This heat of vaporization at atmospheric pressure is transferred from water that remains in a liquid state into the air stream.

WHAT HAPPENS IN PSYCHROMETRIC DIAGRAM?

The air enters at ambient conditions, Point A, absorbs heat and mass (moisture) from the water, and leaves at Point B in a saturated condition (at very low loads, the discharge air may not be fully saturated). . The amount of heat transferred from the water to the air is proportional to the enthalpy difference of the air between the inlet and outlet conditions (hB − hA).

Because the constant enthalpy lines correspond almost exactly to the constant wet bulb temperature lines, the change in enthalpy of the air can be determined by the change in wet bulb air temperature. The heating of the air (Vector AB in Figure 2) can be separated into the AC component, which represents the sensible portion of the heat absorbed by the air as the water cools, and the CB component, which represents the latent portion.

If the inlet air condition changes at point D (at the same wet bulb temperature but at a higher dry bulb temperature), the total heat transfer (Vector DB) remains the same, but the sensible and latent components change. dramatically.

DE represents a sensible cooling of the air, while EB represents latent heating when the water gives up heat and mass to the air. Thus, for the same water cooling load, the ratio of latent to sensible heat transfer can vary significantly.

The relationship between latent and sensible heat is important in the analysis of water in use in a cooling tower.

Mass transfer (evaporation) occurs only in the latent part of heat transfer and is proportional to the change in specific humidity. Because the incoming air dry bulb temperature or relative humidity affects the ratio of latent to sensible heat transfer, it also affects the rate of evaporation.

In Figure 2, the evaporation rate in Case AB (WB − WA) is lower than in Case DB (WB − WD) because latent heat transfer (mass transfer) represents a smaller portion of the total.

Source: Chapter 39 Cooling Towers 2008 ASHRAE Handbook—HVAC Systems and Equipment (SI)

3 - TYPES OF TOWERS

Cooling towers are classified according to several parameters:

-

contact with water

-

Open, the water is directly exposed to the air and thus the heat load is transferred directly to the air

-

Closed, it implies an indirect contact between water and air through an exchanger

-

-

air movement

-

Natural draft, fans are not used for air movement

-

Atmospheric, the air passes through the difference in density and the suction effect (depression) generated by the sprays. The speed of passage is low and therefore conditioned to the speed of the outside air. They are used in applications with a very low budget and benefits.

-

Hyperbolic, used in high power applications. The difference between the density of the air in the tower and outside causes a natural flow of cold air at the bottom and an expulsion of less dense hot air at the top.

-

-

mechanical shot

-

Forced, fan placed at the beginning, drives the air against the current of water (axial or centrifugal fan)

-

Induced, fan placed at the end, sucking the air (axial fan)

-

-

-

By type of fan, depending on the required pressure, noise level and electrical consumption

-

Axial, more efficient but less available pressure if silencers have to be fitted

-

Centrifugal

-

-

Air flow:

-

Against the current, the air moves vertically up through the tower, opposite to the downward flow of water.

-

Crossed, air flows horizontally, traversing the downward flow of water

-

-

Usual type of construction material

-

Concrete

-

Stainless steel

-

Galvanized steel sheet

-

GRP

-

Which are the most used in HVAC and refrigeration systems with chillers?

-

contact with water

-

Open,

-

Closed,

-

-

Air movement, mechanical draft

-

Induced, fan placed at the end, sucking the air (axial fan)

-

Forced, fan placed at the beginning, drives the air against the current of water (axial or centrifugal fan)

-

-

By type of fan,

-

Axial, more efficient but less available pressure if silencers have to be fitted

-

Centrifugal

-

-

Air flow:

-

Against the current, the air moves vertically up through the tower, opposite to the downward flow of water.

-

-

Type of material:

-

Galvanized steel sheet

-

GRP

-

Source: Chapter 39 Cooling Towers 2008 ASHRAE Handbook—HVAC Systems and Equipment (SI)

4 - SIZING

The values to take into account when sizing a tower:

-

Inlet Air Wet Bulb Temperature

-

Range: Water inlet and outlet temperature

-

Water flow

-

Approach: Temperature differential

1- Wet temperature:

For projects that require evaporative cooling, the most demanding percentile wet bulb temperature should be selected (Point A).

For RITE projects, 1ºC must be added to this value. (IT 1.2.4.1.3.4)

2 - Rank:

As required by the chiller, typical values are 35-30ºC (Eurovent Conditions) but may change according to project needs.

Higher head, lower pumping cost but lower chiller efficiency and vice versa. see more

3- Water flow

It must be consistent with the power to be dissipated and the working range.

Must be within the working limits of the chiller condenser

In the case of open towers, there is a minimum operating flow of the tower for the sprays to work correctly.

The flow can be constant, and as an energy efficiency strategy, variable. But the balance between saving pumping consumption and excess consumption in the chiller must be taken into account.see more

4 - Approach

It is the value for the sizing of the tower and the values of investment cost, size and efficiency depend on this value:

⬇️ Low values, implies a larger tower size and therefore a higher investment cost, but improves the efficiency of the chiller in the most demanding outdoor conditions.

⬆️High values, reduce the size, investment costs but reduce the efficiency of the chiller.

Typical value that is usually used, 5ºC but the selection depends on the above factors.

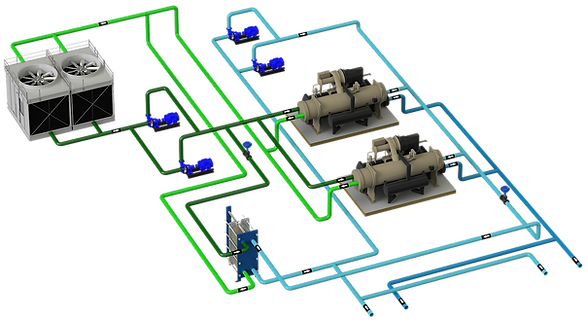

5 - INSTALLATION

Important points to consider when installing towers:

-

Contribution of water, due to losses by evaporation and concentration cycles

-

Automatic drain, to control the concentration of salts

-

Drainage system, visible or monitored, to have a controlled emptying

-

Legionella prevention system, required by law and must be installed and maintained by a licensed company

-

Distance to windows and air intakes (UNE 100030 standard, section 6.1.3.2 or what is indicated in the UNE-EN 13779 standard).see more

-

Sufficient space to avoid the recirculation of saturated air, which would raise the wet bulb temperature of the intake air.

-

Installation height, in open towers the height of the basin must be above the height of the chillers to prevent emptying in a proper stop and start. Pay attention to the NPSH values of the pumps. see more

-

Piping material, compatible with open systems (oxygenation) and biocide treatments

-

Raft equalization tube when you have two or more towers open in parallel

-

Minimum raft level to avoid cavitation problems

-

Balancing valves in each tower when there are two or more towers in parallel

-

Frost protection:

-

Emptying ponds during non-operation

-

Raft heating, by electric resistance

-

Coils in closed towers, add glycol to the installation

-

-

Efficiency of the drop separator, a very important parameter to reduce the risk of dragging drops contaminated by legionella, is expressed by the ratio between the flow of water dragged by the air and the flow of water circulating in the tower; This relationship must be less than 0.05%, according to the UNE 100030 standard.